Small, yet powerful. How to turn by-products into power?

This is the story of small yet powerful pieces, which have high caloric value, are made of by-products and heat us in wintertime.

It is a story about pellets, one of the most appreciated products of HS Timber Group, produced in the factories in Sebeș, Rădăuți, Reci, Comănești and Kodersdorf. In order to turn the raw material into a value-added product, a series of well-established technological processes and a special recipe are necessary.

The pellet recipe:

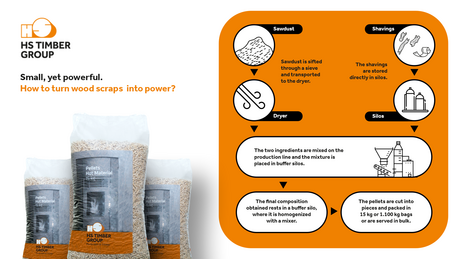

The main ingredients are sawdust and shavings. Sawdust results from cutting the wood and shavings are collected after the timber is planed. The two materials take different paths. Sawdust, like flour, must be sifted through a sieve, to remove large chips. Then, it is transported with the help of specific belts to the dryer, where its humidity is reduced from an initial value of 50 - 60% down to 10%.

On the other hand, the shavings obtained from processed products no longer require drying and are stored directly in silos. The two ingredients are mixed on the production line and the mixture is placed in buffer silos. There, special snails extract it and send it to the hammer mill, where it is crushed until it reaches the desired granulation.

The last ingredient added is the corn-starch, as it binds the entire composition. After this process, the mixture obtained is once again checked for moisture and, if it is too low, water is added.

The final composition obtained rests in a buffer silo, where it is homogenized with a mixer. The last step before it is ready: the mixture is pressed, pushed through a mould. The high temperature, specific to this process, reduces the humidity and activates lignin, a resin contained by wood, which has the role of binding and giving texture to the pellets. Afterwards they are cut into pieces with a maximum length of millimetres.

Now, the pellets are ready!

The pellets are packed in 15 kg or 1.100 kg bags, after which they go to specialised stores. Another way to serve them is in bulk. They are stored in 2.000-tonnes concrete silos. From there, they are transported in special trucks to a bulk loading system.

Interesting facts:

- A press can produce around 4.8 tonnes of pellets in 1 hour

- The 15 kg bag packing machine has the capacity to pack ten tonnes of pellets per hour, while the 1,100 kg bag packing machine can pack up to 30 tonnes per hour

- The caloric power of one kg of pellets stands at more than 4.8 kWh/kg

- The pellets production capacities of HS Timber Group stand at 710,000 tonnes

- Pellets are used for heating and for industrial consumption. We address the market of pellets for heating, which in 2018 stood at 15.7 million tonnes and in 2019 at 16.4 million tonnes.

Consumption of pellets for a family in the south of the European Union stands at between two and three tonnes per year, while in central EU this stands at between three and four tonnes and between four and five tonnes in the north. The average consumption in Romania is of four tonnes per year.