HS Timber Group and TU Wien embark on groundbreaking research for the building material of the future

Vienna, October 13, 2023: The Vienna University of Technology (TU Wien) and HS Timber Group are conducting research on innovative uses for wood chips. To achieve this, a Christian Doppler Laboratory has been established, featuring 15 scientists. The goal is to develop a revolutionary, CO2-neutral building material of the future. The primary focus of this research lies in exploring lignin, a component of wood, and its connections to cellulose fibers. The researchers envision creating 3D-printed construction materials from sawdust.

Wood chips have more potential than simply being compressed into pellets and burned, as believed by HS Timber Group. The company operates several sawmills with further processing facilities in Europe and South America. Only about half of a tree trunk can be turned into boards, while the remaining portion becomes sawdust and chips. Primarily, these by-products are used for pellet production. While this is a local, CO2-neutral heating material, the value chain is limited, and burning wood chips at the outset contradicts the principles of the circular economy.

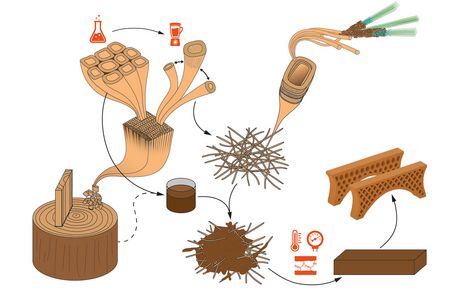

In collaboration with TU Wien, HS Timber Group has initiated a long-term research project to revolutionise the possibilities for utilising wood chips. However, prior to that, the secrets of lignin-cellulose binding must be deciphered. This will be the main task of a team consisting of 15 researchers, led by Dr. Markus Lukacevic. As Lukacevic is aware, the wood structure remains intact even in these small wood pieces. "The smallest building blocks responsible for the properties of wood are preserved during this processing step. They provide stability and strength despite the low weight of wood." Therefore, Markus Lukacevic and his team aim to reassemble these building blocks into macroscopic load-bearing structures sustainably. "The obtained lignocellulose network can be combined into new building materials using shaping or even additive manufacturing processes," explains civil engineer Markus Lukacevic. This process is intended to achieve a similar level of added value as primary wood products.

"For HS Timber Group, it has always been clear that there must be better ways to use wood chips than burning them in the form of pellets. We aim to discover these new options with the 'WoodComp3D' project. As an industrial company working with the sustainable resource of wood, its optimal utilisation is our core business. The Christian Doppler Laboratory at TU Wien is intended to create new possibilities for transforming a by-product into a high-quality material," says Wolfgang Moser, Executive Director of the Evergreen Private Foundation, which owns HS Timber Group.

The total research budget amounts to 9 million Euro, with about one-third provided by HS Timber Group.

Objective: Keeping CO2 bound in wood away from the atmosphere

The key advantage of the new building material is the reduction of greenhouse gas emissions. "Pellets are burned within months, while building materials remain in structures for decades, storing carbon dioxide inside them, keeping it out of the atmosphere. HS Timber Group alone can contribute to reducing CO2 emissions equivalent to half a million cars," outlines Hannes Plackner, responsible for research and development at HS Timber Group.

New biocomposite without the need for adhesives

The research goal is a biocomposite material with high strength and load-bearing capacity. As a long-term vision, even 3D printing from sawdust is being pursued. The critical factor in developing this new material is the wood component lignin, a macromolecule crucial for wood strength. It is extracted from wood chips and reconnected. The proof-of-concept has shown that the original lignin-cellulose bonds can be reactivated through pressure and high temperatures, meaning the new biocomposite is composed solely of wood without the addition of adhesives.

Promoting collaboration between science and industry

The Christian Doppler Research Society represents a best-practice example of national "bottom-up" basic research. It encourages collaborations between companies in the field of application-oriented basic research. The starting point for Christian Doppler Laboratories is a company's innovation goal and related questions. Scientific fundamentals are comprehensively developed in these CD laboratories and Josef Ressel Centers for these issues.

For TU Wien, Christian Doppler Laboratories are a crucial component in extending the value chain in line with the research mission "From scientific foundation to innovation."

About HS Timber Group

HS Timber Group is a long-established wood processing company with Austrian roots and a strong presence in Central and Eastern Europe. The company processes wood in Germany, Finland, and Romania, serving industrial clients worldwide.

About Christian Doppler Laboratories

Christian Doppler Laboratories conduct applied basic research at a high level, with outstanding scientists collaborating with innovative companies. The Christian Doppler Research Society is recognised internationally as a best-practice example for fostering this cooperation. Christian Doppler Laboratories are jointly funded by the public sector and the participating companies, with the Federal Ministry of Labor and Economics (BMAW) being the main public sponsor.

Press Contact HS Timber Group

Johannes Vetter

Press Spokesperson

+43 664 88 578 224

press[at]hs.at

Press Contact WoodComp 3D

Dr. Markus Lukacevic

Vienna University of Technology

Department of Structural Simulation and Timber Engineering

+43 1 58801 20264

markus.lukacevic@tuwien.ac.at

Image Copyright:

© Markus Lukacevic

Image captions: https://www.cdg.ac.at/forschungseinheiten/labor/holzbasiertes-biokomposit-der-naechsten-generation