RESOURCE WOOD

The core of our business is a sustainable resource.

Wood is at the centre of all our activities. This is why sustainability has been an integral part of our identity since our foundation four centuries ago. In the following, we provide an insight into what we do and how we fulfil our responsibility as one of the world's leading wood processing companies. We dedicate ourselves to the fascination of wood and its diverse properties as a sustainable and climate-friendly raw material.

OUR BUSINESS MODEL IS SUSTAINABLE

100 %

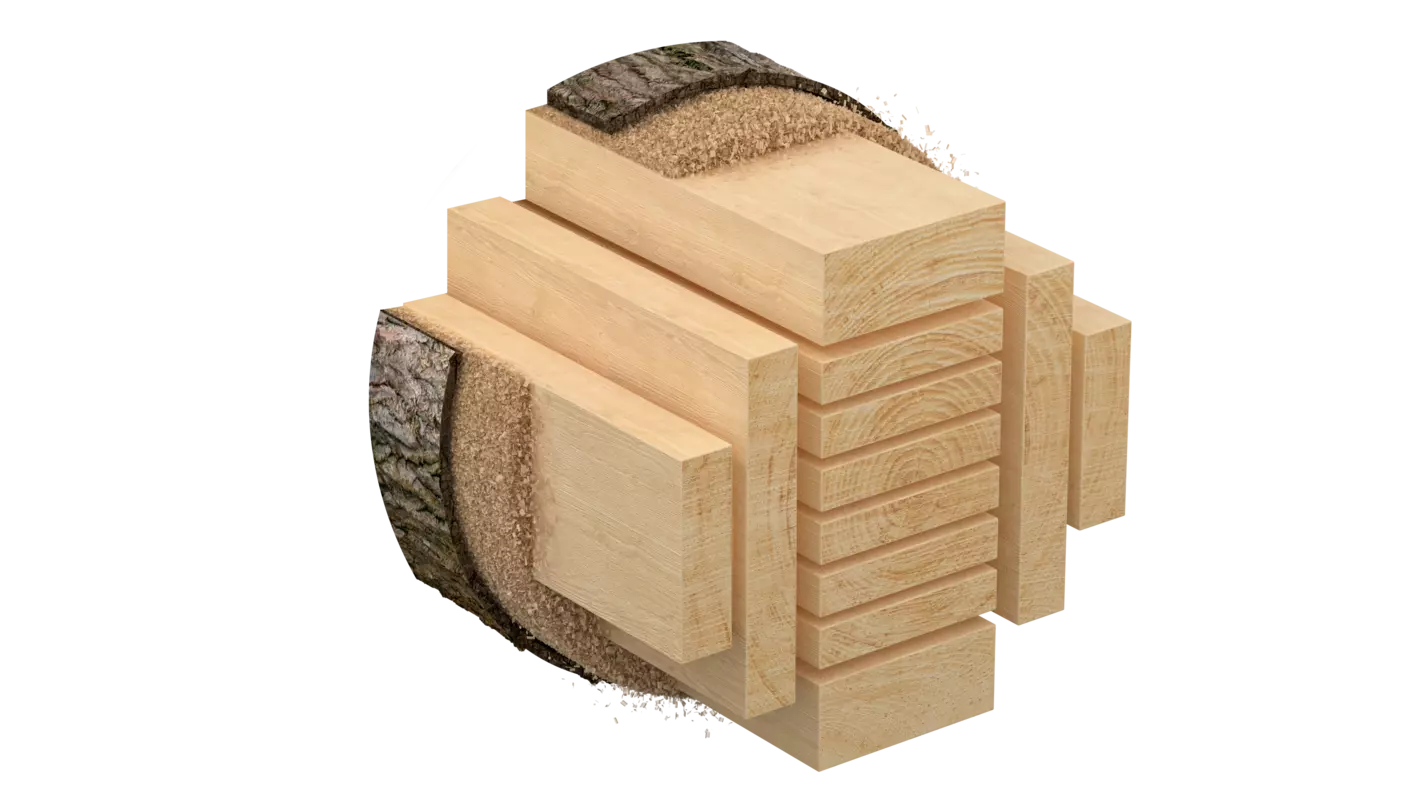

Utilisation of a sawlog

75 %

Timber from certified forests

87 %

Share of own-produced renewable energy of total energy consumption

Responsibility is at the centre of everything we do: in our manufacturing process, we ensure the full utilisation of wood as a raw material. At the same time, we pay attention to energy efficiency and a low ecological footprint.

One cubic metre of wood can store up to 1 tonne of CO2. This climate-positive property of wood from sustainable forestry helps us and our customers to achieve sustainability goals and thus assume social responsibility.

We process conifer roundwood into a wide range of high-quality wood products. We also utilise all sawmill by-products that are produced in our plants. These are either sold to the panel or pulp industry, to biopower plants or processed into high-quality heating pellets. Our pellets are made exclusively from sawmill by-products. This enables us to guarantee consistent high quality.

We use the resulting bark to supply our biomass cogeneration plants and hot water boilers to generate heat for the industrial wood drying process and feed electrical energy into the public grid as green electricity.

Where possible, we replace fossil fuels with renewable energy, e.g. by substituting diesel and petrol vehicles with electric ones. In our photovoltaic systems, we generate electricity for our own production or the local grids.

Finally, we are an important employer in rural areas and we value long-term relationships: We are a reliable partner in the regions in which we operate, as well as for our suppliers and customers worldwide.

A SUSTAINABLE AND TRANSPARENT SUPPLY CHAIN

We source our wood exclusively from sustainably managed forests. Today, 75% of our round timber deliveries already come from forests that are certified for sustainable forestry. We are determined to increase this proportion to 100% by 2030. All our locations are certified for a PEFC Chain of Custody. This is also recognised on the North American market as SFI Label Recognizing Global Standards by the Sustainable Forestry Initiative (SFI). The blockboard plant in Comanesti (Romania) and the sawmills in Luvia (Finland) and Talsi (Latvia) are also certified for an FSC Chain of Custody. For our biomass purchases, we are certified according to SURE.

We monitor our supply chain with great care and go far beyond the legal requirements. We have developed our own traceability system - Timflow - for this purpose. We also carry out regular checks and require our suppliers to comply with the standards set out in the Code of Conduct for Business Partners.

FAQs on HS Timber Group's Supply Chain

Wood is only sustainable if it comes from well-managed forests. This also means that it has to be deforestation free and legally harvested. At HS Timber Group, we use an advanced due diligence system that covers all wooden input materials and includes various steps. This system works at three levels: country, supplier, and delivery. We perform specific risk assessments for each scenario and apply targeted risk mitigation measures down to each delivery. These measures range from requiring extra documentation to conducting onsite audits, from engaging suppliers through programs to suspending those who don't comply. We manage this process with specialised staff based locally and steered from our headquarter in Vienna. This approach ensures the highest integrity in all our deliveries.

Physical traceability is essential for verifying the origin of wooden material. While it's not required by law, we go beyond the basics to ensure transparency. In Romania, alongside the state-run SUMAL system, HS Timber Group launched the Timflow system in 2017: Timflow collects and verifies GPS data, timestamps, and photographs the wood loading process in the forest. Most importantly, we publicly share the origin of each Romanian delivery on our website. We also regularly consult and collaborate with traceability companies to benchmark our methods and stay updated with the latest technologies for tracing wood, including throughout the production process.

Certification is a key tool for promoting good forest management practices worldwide. We hold a PEFC Chain of Custody certification at all our mills and a Sustainable Forestry Initiative® Label Recognizing Global Standards based on the PEFC Chain of Custody. Additionally, our operations in Comanesti (Romania) and Luvia (Finland) have an FSC Chain of Custody certification. For our biomass purchases, we are certified according to SURE.

We support certification not only by obtaining these credentials but also by actively participating in the dialogue with the certification organisations. Forest certification systems are a crucial part of our risk mitigation strategy, complementing our other measures. Believing firmly in the importance of sustainable forest management, our goal is to source all our materials from certified forests by 2030.

Auditing is an effective way to manage risk. Each year, our dedicated supply chain control staff conducts approximately 400 audits. These include both on-site audits, where we verify conditions back to the forest plots, and desk-based audits that involve an in-depth review of documents.

First, we have a clear timber sourcing policy that prohibits purchasing wood from strictly protected areas, such as the core areas of national parks or UNESCO heritage sites and all other virgin forest areas. Given that Romania's national parks do not yet meet the internationally recommended IUCN criteria for a proportion of 75% core areas and 25% buffer zones, we also commit not to source from these buffer zones. Our suppliers must contractually adhere to these rules.

We verify compliance by tracing deliveries back to their origin using Romania's state SUMAL system and our own Timflow system. When materials are processed through log yards, mixing of origins can occur. We usually require our suppliers to keep materials separated in stock, which is checked on-site. We investigate and verify on-site any credible reports of breaches of this policy. Material that evidently originates from such areas is rejected without exception.

To respect human rights requirements internally and within our supply chain, we have issued a policy that reflects our commitment. As a key player in the European and global timber industry, we are aware of our responsibility towards our employees and partners. We strive to promote a corporate culture that emphasizes the importance of complying with fundamental legal requirements in the workplace. To ensure compliance, we continuously monitor national legislation in all the countries where we operate to check if it aligns with the International Labour Organization (ILO) standards. Additionally, our PEFC Chain of Custody certification and FSC Chain of Custody certification at relevant locations ensure regular external reviews of these standards are upheld within our own operation and within our suppliers´ operation.

Like many other companies in Europe and around the world, we are getting ready for the main obligations of the EU Deforestation Regulation (EUDR). We are updating our internal systems to meet the new requirements, which particularly involve collecting geolocation data.

Human Rights

As one of the leaders of the European and global timber industry, we recognise our responsibility towards our employees and partners. This certainly entails the respect of the human rights within our supply chain. Also our corporate culture emphasises the importance of adhering to fundamental legal standards in the workplace. To further anchor this legal commitment both internally and throughout our supply chain, we have issued a specific policy statement and obtained a Chain of Custody certification. This certification ensures that both we and our suppliers are regularly audited to verify our compliance with human rights standards.

You can find and download both documents in the Transparency section of this website.

Health and Safety

At HS Timber Group, the safety of our employees is our top priority. We are committed to maintaining a safe workplace by adhering to stringent occupational health and safety standards and providing regular safety training. Our goal is to prevent all workplace accidents. We involve every employee in our safety initiatives, emphasising that safety starts with each individual, regardless of their role. We comply with legal requirements, maintain our equipment diligently, and ensure all staff have the necessary protective gear. Together, we strive to continuously improve our safety practices and create a workplace culture focused on health and well-being. Our ultimate goal is zero accidents, reflecting our commitment to protecting every member of our team.

Community Engagement

For us, it's not just important to engage in a dialogue with the communities where we operate, but also to genuinely listen to and support their concerns wherever possible. As part of the Evergreen Privatstiftung, our organisation has a long tradition of charitable engagement. Our aim is to provide honest and meaningful support to those who need it most. We focus on education and training for children and youth, as well as supporting equal opportunities for disadvantaged groups.

Naturally, we are committed to integrity and compliance with all rules and regulations that apply to our company. Our mission statement outlines our core values. The Code of Conduct is our internal guideline for conducting business ethically. We also require our suppliers and customers to adhere to a Code of Conduct for Business Partners.

More detailed rules are outlined in our policies, which specifically cover areas such as timber sourcing, environmental management, health and safety, personal data protection, and more.

The most important areas are highlighted here:

HS Timber Group's Code of Conduct forms the basis of our business operations, laying down clear behavioural standards that all employees are required to follow. We operate a state-of-the-art, group-wide compliance management system to manage compliance risks and maintain the highest level of integrity.

"Due Diligence" refers to a careful examination or risk analysis conducted before a business transaction, especially but not limited to buying or selling wood. As a company, we thoroughly review our suppliers and customers before entering any business relationship. We pay particular attention to the inspection and monitoring of our timber supply chain. Moreover, the latter is subject to extensive requirements by external authorities such as the European Timber Regulation (EUTR) or the Regulation on Deforestation-Free Supply Chains (EUDR).

A key element of our compliance management is investigating incidents. Anyone can report putative non-compliant behaviour with rules and regulations by our management, employees, or business partners.

We follow up on every hint. Reports are made under strict confidentiality principles, and our Code of Conduct prohibits any retaliation against the reporting person.

In addition to reporting through this written channel, submissions can also be made directly to the Group Compliance Office.

Compliance Office

Compliance breaches can be reported to our externally hosted whistleblower channel https://hs.vispato.com/whisper or both externally and internally directly to:

Stakeholder Engagement

The stakeholder value is a key success factor for us.

Listening and understanding the concerns of employees, business partners, public officials, and civil society are increasingly important for sustainable business success. Therefore, HS Timber Group is actively engaging in stakeholder dialogue in order to understand the needs and concerns of all our stakeholders. We aim for transparency and stability, precisely by …

- actively sharing our motivations and collecting feedback to understand what matters to our stakeholders,

- providing detailed information about our business practices, and

- specifically engaging with our raw material suppliers to ensure they align with our goals